Versatile and Flammable: Understanding Nitrocellulose and Its Uses

By:Admin

Established in 1998, our company is a leading provider of specialty chemicals and advanced materials. With a strong focus on innovation and sustainability, we strive to deliver high-quality products that meet the evolving needs of our customers. Our commitment to research and development has enabled us to create groundbreaking solutions that cater to a wide range of industries, including automotive, electronics, healthcare, and more. With a global presence and a dedication to excellence, we are proud to be at the forefront of advancements in chemical technology.

*** News Content ***

NITROCELLULOSE: A VERSATILE SOLUTION FOR INDUSTRIAL APPLICATIONS

In today's industrial landscape, the demand for high-performance materials that offer both versatility and reliability continues to grow. One such material that has been instrumental in meeting these requirements is 1/8 nitrocellulose. Renowned for its exceptional properties, nitrocellulose has emerged as a popular choice for a wide range of industrial applications, from automotive coatings to electronics manufacturing.

Our company, a leading provider of specialty chemicals and advanced materials, has been at the forefront of developing and supplying high-quality 1/8 nitrocellulose to meet the evolving demands of the industry. Leveraging our expertise in chemical technology and commitment to innovation, we have consistently delivered superior nitrocellulose products that have set the benchmark for performance and quality.

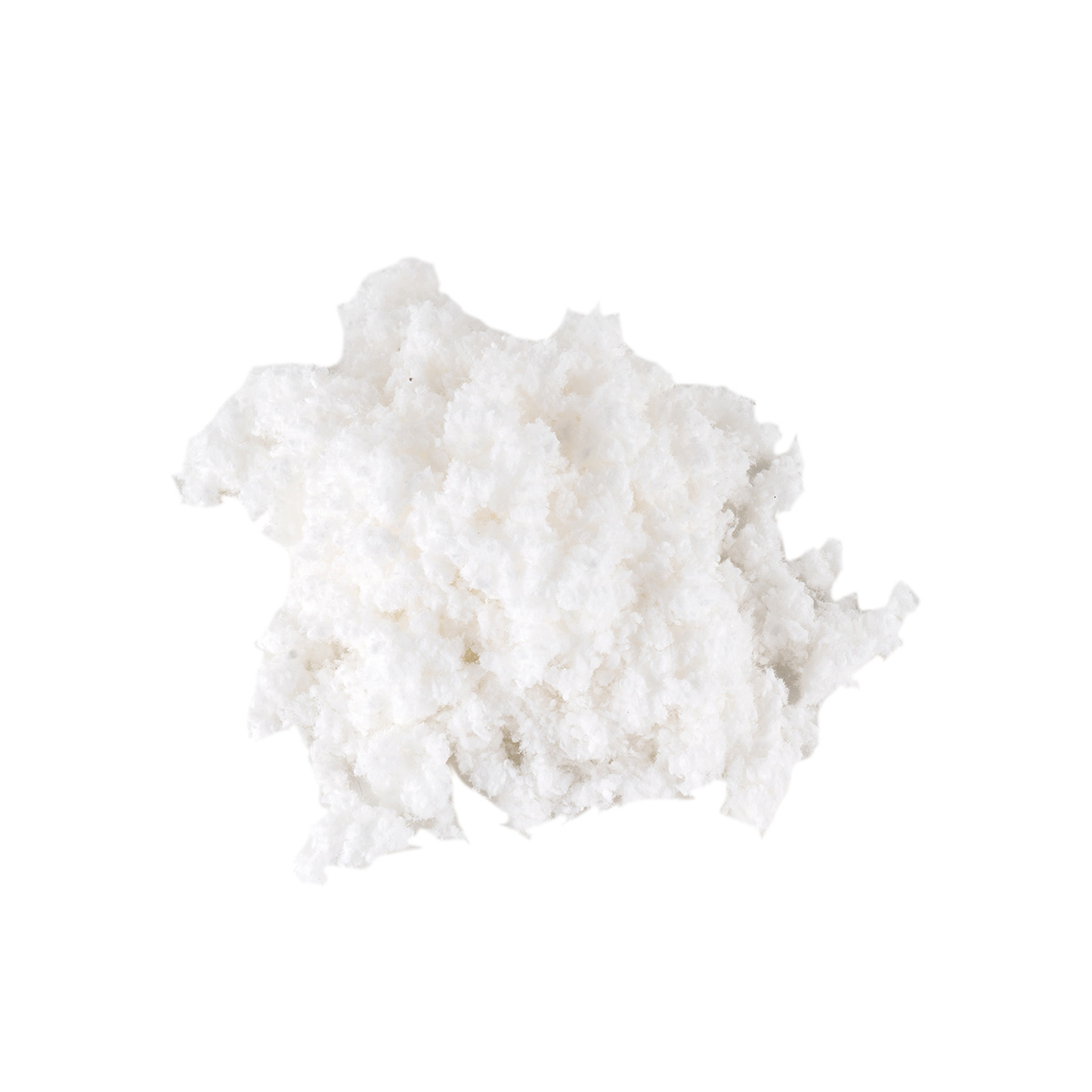

1/8 Nitrocellulose, also known as guncotton, is a highly flammable compound produced by nitrating cellulose through exposure to nitric acid or other powerful nitrating agents. The resulting material offers a unique combination of properties, including high tensile strength, chemical resistance, and excellent film-forming capabilities. These characteristics make 1/8 nitrocellulose an ideal choice for a diverse range of industrial applications.

In the automotive industry, our 1/8 nitrocellulose has been widely used in the formulation of high-quality coatings and finishes. Whether it's for automotive paints, clear coats, or primers, our nitrocellulose products have proven to provide outstanding adhesion, durability, and gloss, making them essential for achieving superior surface finishes on vehicles.

Furthermore, in the electronics industry, our nitrocellulose is utilized in the production of specialty films and membranes. Its exceptional film-forming properties and ability to withstand harsh environmental conditions make it an excellent choice for applications such as membrane switches, flexible circuit boards, and other electronic components that require reliable and durable materials.

Additionally, 1/8 nitrocellulose has found its way into the healthcare sector, where it is used in the manufacturing of medical adhesives and wound dressings. The material's biocompatibility, film-forming capabilities, and adhesion properties make it a valuable component in medical applications, where sterile and reliable materials are of utmost importance.

At our company, we take pride in our ability to supply high-quality 1/8 nitrocellulose that meets the exacting standards of various industries. Through our state-of-the-art manufacturing facilities and stringent quality control measures, we ensure that our nitrocellulose products consistently deliver exceptional performance and reliability, while adhering to the highest industry standards for safety and environmental sustainability.

Moreover, our dedication to research and development has enabled us to push the boundaries of nitrocellulose technology, leading to the development of advanced formulations with enhanced properties, such as improved flexibility, faster drying times, and reduced volatility. These advancements underscore our commitment to continually innovate and offer our customers cutting-edge solutions that address their evolving needs.

As the demand for high-performance materials continues to grow across various industrial sectors, 1/8 nitrocellulose is poised to play a significant role in meeting these demands. With our expertise and unwavering commitment to excellence, we are well-positioned to continue providing top-quality nitrocellulose solutions that drive innovation and deliver value to our customers worldwide.

In conclusion, 1/8 nitrocellulose stands as a versatile and indispensable material for a wide array of industrial applications, and our company is dedicated to supplying the highest quality nitrocellulose products that meet the evolving needs of our customers. As the industry evolves, we remain committed to innovation, sustainability, and excellence, ensuring that our nitrocellulose solutions continue to set the standard for performance and quality.

Company News & Blog

New Cellulose Food Packaging Offers Sustainable and Eco-Friendly Storage Solution

Cellulose Food Packaging is becoming increasingly popular in the food industry as a sustainable and eco-friendly alternative to traditional plastic packaging. One company at the forefront of this innovative technology is {} (). They have been leading the way in developing and producing cellulose-based packaging solutions that offer a sustainable and biodegradable option for food packaging. With the growing concern around single-use plastics and their impact on the environment, {}'s cellulose food packaging provides a viable solution that meets the needs of both consumers and the planet.{} has been a leader in the packaging industry for over 20 years and has a strong commitment to sustainability and innovation. Their focus on research and development has led to the creation of cellulose-based food packaging that is not only environmentally friendly but also meets the high standards of quality and functionality required in the food industry. Their expertise and dedication to sustainability have positioned them as a trusted partner for food companies looking to reduce their environmental impact without compromising on the safety and preservation of their products.{}'s cellulose food packaging is made from renewable and biodegradable materials, primarily derived from plant-based sources such as wood pulp. This makes it an ideal solution for food companies looking to reduce their reliance on plastic packaging and transition to more sustainable options. The cellulose-based packaging offers the same level of protection and preservation as traditional plastic packaging, ensuring that food products remain fresh and safe for consumption while also being environmentally responsible.One of the key advantages of {}'s cellulose food packaging is its ability to biodegrade naturally, reducing the environmental impact of food packaging waste. This is particularly important for food companies and consumers alike, as the global push towards sustainability and reducing plastic waste continues to gain momentum. By choosing cellulose food packaging from {}, food companies can demonstrate their commitment to environmental responsibility while also meeting the evolving preferences of consumers who are increasingly seeking out sustainable products.In addition to being biodegradable, {}'s cellulose food packaging is also compostable, further adding to its appeal as a sustainable packaging solution. This means that after use, the packaging can be disposed of in a composting environment, where it will naturally break down into organic matter without leaving behind harmful residues or contributing to the growing issue of plastic pollution. This aligns with the circular economy model, where materials are designed to be reused, recycled, or composted, minimizing waste and reducing the burden on the environment.The versatility of {}'s cellulose food packaging also extends to its ability to be customized to meet the specific needs of food companies. Whether it's for fresh produce, baked goods, or ready-to-eat meals, the packaging can be tailored to provide the necessary protection and shelf life for different types of food products. This flexibility, combined with the sustainable and eco-friendly nature of the packaging, makes it an ideal choice for food companies looking to align their packaging solutions with their sustainability goals and consumer preferences.As the demand for sustainable packaging solutions continues to grow, {} remains committed to driving innovation in cellulose food packaging and providing food companies with a reliable and environmentally responsible choice for their packaging needs. With a strong track record of delivering high-quality packaging solutions and a focus on sustainability, {} is well-positioned to continue leading the way in the development and adoption of cellulose-based packaging in the food industry.In conclusion, the cellulose food packaging offered by {} presents a compelling and sustainable alternative to traditional plastic packaging for food companies. With its biodegradable and compostable properties, as well as its customization options, {}'s cellulose food packaging is poised to play a significant role in reducing the environmental impact of food packaging waste and meeting the growing demand for sustainable packaging solutions in the food industry. As a trusted leader in the packaging industry, {}'s dedication to sustainability and innovation positions them as a valuable partner for food companies looking to embrace environmentally responsible packaging solutions.

Renewable Fuel Ethanol Ester: What You Need to Know

Ethanol Ester is making headlines in the world of renewable fuel sources, and for good reason. The company has developed a groundbreaking technology that is revolutionizing the way we produce and use ethanol. This innovative process promises to significantly reduce greenhouse gas emissions and make a positive impact on the environment.Ethanol Ester is a leading company in the renewable energy industry, with a focus on producing sustainable ethanol. The company has been at the forefront of developing new technologies and processes that aim to reduce the carbon footprint of ethanol production. Their latest breakthrough, the Ethanol Ester, is a game-changer in the field of renewable energy.The Ethanol Ester technology is based on a proprietary process that uses a novel catalyst to convert ethanol into ethyl acetate, a high-value chemical compound. This process has several key advantages over traditional ethanol production methods. Not only does it result in a more efficient and cost-effective conversion process, but it also reduces the carbon intensity of the end product.One of the most significant benefits of Ethanol Ester technology is its potential to significantly reduce greenhouse gas emissions. Traditional ethanol production processes are energy-intensive and often rely on fossil fuels, leading to high levels of CO2 emissions. Ethanol Ester's innovative technology, however, has the potential to lower the carbon intensity of ethanol by up to 30%, making it a much more sustainable and environmentally-friendly option.In addition to its environmental benefits, Ethanol Ester also offers economic advantages. The production of ethyl acetate from ethanol opens up new markets and revenue streams for ethanol producers. Ethyl acetate is a versatile compound used in a wide range of industries, including pharmaceuticals, food and beverage, and personal care products. By diversifying the applications of ethanol, Ethanol Ester creates new opportunities for ethanol producers to increase their profitability and sustainability.The potential impact of Ethanol Ester technology is not limited to the ethanol industry. The company's innovative approach to renewable energy has the potential to influence other sectors and industries. The development of new, sustainable technologies like Ethanol Ester demonstrates the importance of innovation in addressing the environmental challenges we face today.Ethanol Ester's commitment to sustainability and environmental responsibility sets the company apart as a leader in the renewable energy industry. The company has made significant investments in research and development to bring this groundbreaking technology to fruition. By focusing on improving the environmental performance of ethanol production, Ethanol Ester is taking a proactive approach to addressing climate change and advancing the transition to a low-carbon economy.As the demand for sustainable energy solutions continues to grow, Ethanol Ester's technology will play a crucial role in meeting these demands. By providing a more environmentally-friendly alternative to traditional ethanol production, Ethanol Ester is helping to drive the transition towards a greener and more sustainable future.In conclusion, Ethanol Ester's innovative technology has the potential to revolutionize the way we produce and use ethanol. By significantly reducing the carbon intensity of ethanol production, Ethanol Ester is paving the way for a more sustainable and environmentally-friendly future. The company's commitment to innovation and sustainability make it a key player in the renewable energy industry, and its technology has the potential to make a lasting impact on the world.

New Nitrocellulose Nc Technology Transforming the Industry

Nitrocellulose (NC) has been revolutionizing the world of materials and coatings with its unique properties and wide array of applications. The company behind this groundbreaking product, known for its commitment to innovation and excellence, is a leader in the research, development, and production of high-quality nitrocellulose-based products.With a history of over [X] years of experience in the industry, the company has established itself as a trusted name in the market, renowned for its dedication to quality and customer satisfaction. Its state-of-the-art facilities and cutting-edge technology have enabled it to consistently deliver top-of-the-line nitrocellulose products that meet and exceed industry standards.Nitrocellulose, a highly flammable compound produced by nitrating cellulose through exposure to nitric acid or another powerful nitrating agent, has found widespread use in a variety of industrial applications. The unique properties of nitrocellulose, including its high film-forming ability, excellent adhesion, and quick drying time, make it an ideal choice for use in products such as lacquers, paints, printing inks, and vinyl coatings.One of the most significant advantages of nitrocellulose-based products is their versatility. They can be tailored to meet the specific needs of different industries, offering a wide range of viscosities, solubilities, and other characteristics to ensure optimal performance in various applications. From automotive coatings to wood finishes, nitrocellulose products have proven to be indispensable across a broad spectrum of fields.Moreover, nitrocellulose is renowned for its environmentally friendly nature. As a renewable and biodegradable raw material, it aligns with the growing global emphasis on sustainable and eco-friendly products. The company has made significant strides in developing environmentally conscious formulations and processes to ensure that its nitrocellulose products are in harmony with the environment.The company's commitment to research and development has been instrumental in driving the continuous improvement and innovation of its nitrocellulose products. By staying at the forefront of technological advancements and market trends, the company has been able to consistently introduce new and improved formulations that set new benchmarks for quality and performance.The company's dedication to quality is evident in its rigorous quality control measures and adherence to international standards. Its products undergo comprehensive testing and analysis to ensure that they meet the highest specifications and deliver exceptional results consistently. This unwavering commitment to quality has earned the company a stellar reputation and the trust of customers worldwide.In addition to its focus on product excellence, the company places a strong emphasis on customer satisfaction and collaboration. It works closely with its clients to understand their specific requirements and develop tailored solutions that address their unique needs effectively. This customer-centric approach has been fundamental in building long-lasting partnerships and driving mutual success.As the demand for high-performance coatings and materials continues to grow, the company is poised to lead the way with its superior nitrocellulose products. With an unwavering commitment to innovation, quality, and sustainability, it is set to redefine industry standards and create new opportunities for businesses across various sectors.In conclusion, the company's expertise and dedication have positioned it as a trailblazer in the nitrocellulose industry. Its commitment to excellence, innovation, and customer satisfaction underscores its role as a key player in delivering top-tier nitrocellulose products that set the bar for quality and performance. With a focus on sustainability and collaboration, the company is well-equipped to shape the future of the industry and meet the evolving needs of a dynamic market.

The Advantages of Refined Cotton Cellulose: Uses and Benefits

Refined Cotton Cellulose: A Revolutionary Innovation in Sustainable Textile IndustryIn recent years, the global fashion and textile industry has been facing increasing pressure to adopt sustainable practices in response to growing consumer awareness and concern for the environment. As a result, textile companies have been seeking innovative solutions to reduce their environmental footprint while still meeting the demands of the market. One such solution that has emerged as a game-changer in the industry is the use of Refined Cotton Cellulose, a revolutionary product that is transforming the way textiles are produced.Refined Cotton Cellulose, produced by the renowned company, [Company Name], is a sustainable and eco-friendly alternative to traditional textile materials. It is derived from renewable resources, primarily cotton, and is processed using an advanced and environmentally-friendly production process. This innovative material has garnered attention for its ability to address the environmental impact of textile production while also delivering high-quality and versatile textiles.[Company Name] is a pioneer in the development and production of Refined Cotton Cellulose. With a commitment to sustainability and innovation, the company has invested heavily in research and development to create a product that meets the growing demand for sustainable textiles. By leveraging its expertise in textile technology and manufacturing, [Company Name] has successfully positioned itself as a leader in the sustainable textile industry, offering a range of products that are not only environmentally friendly but also commercially viable.The use of Refined Cotton Cellulose has several benefits that have made it a preferred choice for textile companies looking to adopt sustainable practices. Firstly, it reduces the reliance on non-renewable resources, such as petroleum-based materials, which are typically used in the production of traditional textiles. By utilizing renewable resources like cotton, [Company Name] has been able to minimize the environmental impact of its products, while also contributing to the reduction of carbon emissions.Furthermore, Refined Cotton Cellulose is biodegradable, making it an attractive option for companies looking to minimize the environmental impact of their products throughout their lifecycle. Unlike synthetic materials that contribute to plastic waste accumulation, textiles made from Refined Cotton Cellulose can naturally decompose, reducing the burden on landfills and the environment.In addition to its environmental benefits, Refined Cotton Cellulose also offers superior performance and versatility, making it an ideal choice for a wide range of textile applications. The material can be tailored to meet specific requirements, such as strength, durability, and moisture-wicking properties, making it suitable for use in various products, from apparel and home textiles to technical textiles and nonwovens. This versatility has made Refined Cotton Cellulose a preferred option for brands and consumers looking for sustainable and high-performance textiles.The adoption of Refined Cotton Cellulose by leading textile companies has played a significant role in shaping the future of the industry. As consumer demand for sustainable products continues to grow, textile companies are increasingly recognizing the importance of integrating environmentally friendly materials into their product offerings. By leveraging the benefits of Refined Cotton Cellulose, companies can differentiate themselves in the market, align with consumer values, and contribute to a more sustainable future for the textile industry.Looking ahead, [Company Name] remains committed to driving innovation in the sustainable textile industry and further expanding the applications of Refined Cotton Cellulose. Through ongoing research and development, the company aims to introduce new and advanced forms of the material, catering to the evolving needs of the market and solidifying its position as a leader in sustainable textile solutions.In conclusion, Refined Cotton Cellulose has emerged as a revolutionary innovation in the textile industry, offering a sustainable and eco-friendly alternative to traditional materials. With its environmental benefits, superior performance, and versatility, Refined Cotton Cellulose is reshaping the landscape of textile production and driving the industry towards a more sustainable future. As companies continue to embrace sustainable practices, the adoption of Refined Cotton Cellulose is set to become a key driver of change in the textile industry, paving the way for a more environmentally conscious and responsible approach to production. As a result, [Company Name] and its Refined Cotton Cellulose are at the forefront of this evolving industry, pioneering new standards for sustainable textiles and setting a benchmark for others to follow.

Top A-Grade Nitrocellulose Solution Supplier in China

China A-Grade Nitrocellulose Solution SupplierChina is known for its high-quality chemical products and is a leading supplier of various industrial chemicals. One such company that has made a name for itself in the chemical industry is a leading A-grade Nitrocellulose solution supplier based in China. The company has established itself as a reliable and reputable supplier of Nitrocellulose solutions to various industries across the globe.The company has a strong presence in the chemical industry and has been serving its clients with high-quality nitrocellulose solutions for many years. With a focus on quality, reliability, and customer satisfaction, the company has built a solid reputation in the industry.The A-grade Nitrocellulose solutions supplied by the company are used in a wide range of applications, including automotive paints, wood finishes, printing inks, and lacquers. The company's products are known for their superior quality, consistency, and reliability, making them a preferred choice for many industries.The company has invested heavily in research and development to ensure that its products meet the highest standards of quality and performance. This commitment to innovation has enabled the company to stay ahead of the competition and provide its customers with the best possible solutions for their needs.In addition to its focus on product quality, the company also places a strong emphasis on environmental sustainability and safety. It has implemented strict quality control measures to ensure that its products meet all relevant safety and environmental standards. This commitment to sustainability has earned the company a strong reputation as a responsible and ethical supplier in the industry.The company has also established strong relationships with its customers, providing them with the support and guidance they need to make informed decisions about their nitrocellulose solution requirements. Its dedicated customer service team is always available to assist customers with any questions or concerns they may have, ensuring that they receive the best possible service and support.As a leading A-grade Nitrocellulose solution supplier in China, the company is committed to maintaining its position as a trusted and respected supplier in the industry. It continues to invest in the latest technology and manufacturing processes to ensure that its products remain at the forefront of the industry.The company's dedication to quality, innovation, and customer satisfaction has helped it to become a preferred supplier of A-grade Nitrocellulose solutions for many industries. Its products are trusted by customers around the world for their superior quality, performance, and reliability.With a strong focus on research and development, environmental sustainability, and customer support, the company is well-positioned to continue its success as a leading A-grade Nitrocellulose solution supplier in China and beyond.In conclusion, the A-grade Nitrocellulose solution supplier in China is committed to providing its customers with the highest quality nitrocellulose solutions for their industrial needs. With a focus on innovation, sustainability, and customer satisfaction, the company has established itself as a trusted and reliable supplier in the industry. Its dedication to quality and excellence ensures that its products remain at the forefront of the industry, making it a preferred choice for customers around the world.

The Importance of Linters in Cotton: What You Need to Know

linters in cotton (need to remove brand name) have become a key focus within the textile industry. With the increasing demand for sustainable and eco-friendly products, companies are looking for innovative ways to enhance the quality of their textiles while also improving their environmental footprint. This is where the expertise of the company comes into play.As a leading supplier of cotton linters, the company is dedicated to providing high-quality products that meet the needs of the modern textile industry. Their commitment to sustainability and innovation has made them a trusted partner for textile manufacturers around the world.Cotton linters are a valuable by-product of the cotton ginning process. They are the short fibers that remain on the cotton seed after the longer fibers have been removed. These linters are rich in cellulose and can be used to create a wide range of products, including high-quality textiles.The company has developed a unique process for extracting and refining cotton linters, ensuring that their products meet the highest standards of quality and sustainability. By utilizing cutting-edge technology and sustainable practices, they are able to provide their customers with linters that are not only superior in quality but also environmentally friendly.One of the key advantages of using cotton linters in textiles is their excellent absorbency and softness. These properties make them ideal for creating textiles that are not only comfortable to wear but also durable and long-lasting. In addition, cotton linters are biodegradable, making them a more sustainable choice compared to synthetic fibers.The company also offers a range of customized linters for specific textile applications. Whether it's for high-end fashion garments or everyday household textiles, their team of experts can work with customers to develop linters that meet their unique requirements. This level of customization allows textile manufacturers to create products that stand out in the market, setting them apart from competitors.In addition to their commitment to quality and sustainability, the company's dedication to customer satisfaction sets them apart in the industry. They work closely with their customers to understand their needs and provide personalized solutions that meet their specific requirements. This customer-focused approach has earned them a strong reputation for reliability and excellence in the textile industry.As the demand for sustainable and high-quality textiles continues to grow, the role of cotton linters in the industry will only become more significant. By working with a trusted supplier like the company, textile manufacturers can ensure that they are using top-quality linters that enhance the value of their products while also contributing to a more sustainable future.In conclusion, the company is at the forefront of providing high-quality and sustainable linters in the textile industry. Their commitment to innovation, sustainability, and customer satisfaction has made them a trusted partner for textile manufacturers around the world. With their expertise and dedication, they are poised to play a key role in shaping the future of the textile industry.

Bamboo Cellulose: A Sustainable and Eco-Friendly Material

Bamboo Cellulose - The Sustainable Solution for the FutureIn a world where sustainability is becoming an increasingly important concern, companies are constantly seeking innovative and eco-friendly solutions to meet the demands of the market. One such company, (remove brand name), has been at the forefront of sustainability efforts, and their latest innovation, Bamboo Cellulose, is set to revolutionize the industry.Bamboo Cellulose is a versatile and sustainable material that is derived from bamboo plants. Bamboo is known for its rapid growth and low environmental impact, making it an ideal source for a wide range of products. (Remove brand name) has harnessed the potential of bamboo to create a highly functional and eco-friendly cellulose material that can be used in various applications.The company has developed a proprietary process for extracting cellulose from bamboo, ensuring that the material is of the highest quality and purity. This process also allows for the efficient use of resources, minimizing waste and environmental impact. As a result, Bamboo Cellulose is a truly sustainable alternative to traditional materials, such as cotton or synthetic fibers.One of the key benefits of Bamboo Cellulose is its versatility. It can be used to create a wide range of products, including textiles, paper, packaging, and more. The material is known for its softness, breathability, and durability, making it suitable for use in various consumer and industrial applications. Additionally, Bamboo Cellulose is biodegradable, further contributing to its eco-friendly credentials.In addition to its environmental advantages, Bamboo Cellulose also offers significant benefits in terms of performance and quality. The material is naturally antibacterial and hypoallergenic, making it ideal for use in sensitive applications, such as clothing and bedding. It also has excellent moisture-wicking properties, making it suitable for activewear and other performance-oriented products.Furthermore, (remove brand name) is committed to ensuring the responsible and ethical production of Bamboo Cellulose. The company works closely with bamboo growers and suppliers to ensure that their practices are sustainable and environmentally friendly. They also prioritize fair labor practices and transparent supply chains, ensuring that the entire production process upholds the highest standards of ethics and sustainability.The introduction of Bamboo Cellulose is a testament to (remove brand name)'s dedication to innovation and sustainability. By offering a viable alternative to traditional materials, the company is not only meeting the current demand for eco-friendly products but also contributing to a more sustainable future.The market potential for Bamboo Cellulose is vast, as consumers and businesses alike are increasingly seeking sustainable alternatives. The material's extensive range of applications, coupled with its environmental and performance advantages, positions it as a highly attractive option for a wide range of industries.As the global community continues to prioritize sustainability, materials like Bamboo Cellulose are set to play a crucial role in shaping the future of various industries. (remove brand name) is at the forefront of this movement, leading the way with their innovative and sustainable solutions.Moving forward, (remove brand name) is committed to further developing and refining Bamboo Cellulose, as well as exploring new applications and opportunities for the material. The company's dedication to sustainability and innovation ensures that Bamboo Cellulose will continue to make a significant impact in the market, offering a sustainable solution for the future.

Top Ethanol Nitrocellulose Exporter in the Industry

Ethanol and nitrocellulose are important industrial chemicals that are widely used in various manufacturing processes. One company that is making a significant impact in the export of ethanol and nitrocellulose is a leading chemical exporter based in {company location}, {company name}. With a strong focus on quality and customer satisfaction, {company name} has become a trusted supplier of these essential chemicals to numerous industries around the world.Ethanol, also known as ethyl alcohol, is a renewable fuel that is commonly used as a solvent, a disinfectant, and in the production of alcoholic beverages. It is also used as an ingredient in the manufacturing of personal care products, pharmaceuticals, and industrial chemicals. Nitrocellulose, on the other hand, is a highly flammable compound that is used in the production of explosives, lacquers, and as a binding agent in the manufacturing of smokeless gunpowder.{company name} has established itself as a leading exporter of ethanol and nitrocellulose, with a strong emphasis on meeting the highest quality standards and ensuring the timely delivery of products to its customers. The company has built long-standing relationships with prominent manufacturers and distributors in the global market, and has gained a reputation for its reliability and efficiency in fulfilling orders.With a state-of-the-art production facility and a dedicated team of experts, {company name} is able to consistently produce and supply large quantities of ethanol and nitrocellulose to meet the diverse needs of its clients. The company's commitment to research and development has also allowed it to stay ahead of the curve in terms of product innovation and quality control, ensuring that its customers receive nothing but the best.In addition to its focus on product quality, {company name} is also committed to environmental sustainability and safety in all aspects of its operations. The company adheres to strict safety protocols and environmental regulations in the production and transportation of its chemicals, and is constantly seeking ways to minimize its carbon footprint and impact on the environment.{company} primarily exports its ethanol and nitrocellulose to a wide range of industries, including pharmaceuticals, personal care products, automotive, and defense. With a strong global network of distributors and partners, the company has been able to reach markets in Asia, Europe, North America, and beyond, establishing itself as a key player in the international chemical trade.Looking towards the future, {company name} is poised to continue its trajectory of growth and success in the export of ethanol and nitrocellulose. The company has plans to expand its production capacity and streamline its supply chain to meet the increasing demand for its products in the global market. Additionally, {company name} is exploring opportunities to diversify its product range and offer new, innovative chemicals to its clients.In conclusion, {company name} has solidified its position as a premier exporter of ethanol and nitrocellulose, with a strong commitment to quality, reliability, and sustainability. The company's dedication to excellence and customer satisfaction has earned it a stellar reputation in the international chemical trade, and it is well-poised for continued success in the years to come.

The Use of Methyl Ethyl Cellulose in Various Industries

Methyl Ethyl Cellulose Market Growing with Increasing Demand from Construction and Pharmaceutical IndustriesMethyl Ethyl Cellulose (MEC) is a versatile product that has a wide range of applications in various industries, including construction, pharmaceutical, food, and cosmetics. MEC is a non-ionic water-soluble cellulose ether that is derived from natural polymer cellulose and is commonly used as a thickener, stabilizer, and emulsifier in various products.In the construction industry, MEC is widely used as a binder and film-former in the production of dry-mix mortars, tile adhesives, grouts, and cement-based plasters. It improves the water retention, workability, and adhesion properties of these construction materials, making them easier to handle and apply. Moreover, it enhances the durability and long-term performance of these products, making them suitable for a wide range of applications in the construction industry.In the pharmaceutical industry, MEC is used as a binder and disintegrant in the production of tablets and capsules. It plays a crucial role in controlling the release of active pharmaceutical ingredients, ensuring the uniformity and consistency of the dosage, and improving the stability and bioavailability of the drugs. Moreover, MEC is also used in the production of ophthalmic solutions, suspensions, and topical formulations, where it acts as a viscosity enhancer and stabilizer.In the food industry, MEC is used as a thickener, stabilizer, and emulsifier in various products, including sauces, dressings, and dairy products. It helps improve the texture, mouthfeel, and shelf-life of these food products, making them more appealing to consumers. Moreover, MEC is also used in the production of low-fat and low-calorie food products, where it replaces the fat and sugar content without compromising the taste and quality.In the cosmetics industry, MEC is used as a film-former, thickener, and emulsifier in various skincare and haircare products. It helps improve the texture, spreadability, and stability of these cosmetic products, making them more effective and user-friendly. Moreover, MEC is also used in the production of sunscreens, lotions, and creams, where it acts as a viscosity modifier and emollient.{Company} is a leading manufacturer and supplier of Methyl Ethyl Cellulose (MEC) with a strong presence in the global market. The company has a state-of-the-art manufacturing facility that is equipped with advanced production technologies and quality control systems to ensure the highest standards of product quality and consistency. Moreover, the company has a team of experienced professionals who are dedicated to research and development, product innovation, and customer satisfaction.{Company} offers a wide range of MEC products that are tailored to meet the specific requirements of different industries and applications. The company's MEC products are known for their superior performance, reliability, and cost-effectiveness, making them a preferred choice for many customers worldwide. Moreover, the company provides comprehensive technical support, custom formulations, and on-time delivery services to ensure the success of its customers' projects and businesses.With the growing demand for MEC in the construction and pharmaceutical industries, {Company} is committed to expanding its production capacity, improving its product portfolio, and strengthening its global distribution network. The company is also focused on developing sustainable and eco-friendly MEC products that align with the industry's evolving regulatory requirements and environmental standards.In conclusion, Methyl Ethyl Cellulose (MEC) is a valuable product that plays a significant role in various industries, including construction, pharmaceutical, food, and cosmetics. With its wide range of applications and benefits, MEC is expected to continue growing in demand and popularity in the global market. {Company} is at the forefront of this growth, offering high-quality MEC products and solutions to meet the evolving needs of its customers and the industry as a whole.

Nitrocellulose and Water Mix: Properties and Uses

Nitrocellulose is a highly versatile and innovative material that has a wide range of applications across various industries. When combined with water, it forms a unique solution that has numerous uses in fields such as paint, coatings, and textiles. One company that has been at the forefront of developing and utilizing nitrocellulose with water is (remove brand name).As a leading provider of nitrocellulose and other chemical products, (remove brand name) has a long history of innovation and excellence in the industry. With state-of-the-art manufacturing facilities and a team of skilled professionals, the company has been able to develop high-quality nitrocellulose products that meet the diverse needs of its customers.The combination of nitrocellulose with water has been a game-changer for many industries, thanks to its unique properties and advantages. When dissolved in water, nitrocellulose forms a colloid solution that can be easily applied to various surfaces. This solution has excellent adhesive properties, making it an ideal ingredient for paints, coatings, and adhesives.In the paint and coatings industry, nitrocellulose with water is widely used as a film-forming agent. It provides a smooth and durable finish to surfaces, making it a popular choice for automotive and industrial coatings. Additionally, the water-based nature of this solution makes it more environmentally friendly compared to traditional solvent-based coatings.The textile industry has also benefited greatly from the use of nitrocellulose with water. This solution is used as a coating for fabrics, providing them with enhanced strength and durability. It also improves the printability of textiles, making it easier to apply designs and patterns onto various materials.One of the key advantages of using nitrocellulose with water is its versatility. It can be easily customized to meet the specific requirements of different applications, making it a highly adaptable solution for various industries. Additionally, its fast-drying nature and excellent adhesion properties make it a preferred choice for many manufacturers.As a leading supplier of nitrocellulose with water, (remove brand name) has been working closely with its customers to develop tailored solutions that meet their unique needs. The company's technical expertise and commitment to quality have made it a trusted partner for businesses looking to incorporate nitrocellulose with water into their products.In addition to its technical capabilities, (remove brand name) is also dedicated to sustainability and environmental responsibility. The company places a strong emphasis on developing eco-friendly solutions that minimize the impact on the environment. By offering water-based nitrocellulose products, it is helping its customers reduce their carbon footprint and meet their sustainability goals.Looking ahead, (remove brand name) is committed to continuing its research and development efforts to further enhance the capabilities of nitrocellulose with water. The company sees great potential for this material in a wide range of applications, and is focused on exploring new opportunities to expand its usage.Overall, nitrocellulose with water has proven to be a highly valuable and versatile solution for numerous industries. With (remove brand name) actively driving its development and utilization, the future looks bright for this innovative material.